Mining safety production has always been the focus of attention from all walks of life. Monolithic hydraulic acrow props are the key machinery and equipment used in mining safety production. We have a better understanding of basic equipment maintenance skills. The following is the hydraulic acrow props basic common failure response methods of the hydraulic acrow props.

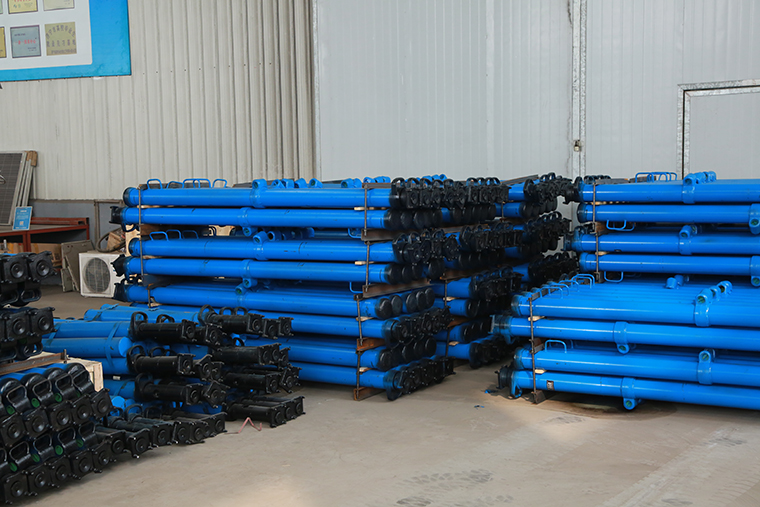

Hydraulic Acrow Props in our factory

Local scratches and deformations of hydraulic acrow props equipment are common problems with hydraulic acrow props, especially problems such as piston port deformation and leakage, and underground hydraulic acrow props corrosion. Due to the difficulty of disassembling the equipment, traditional methods are often difficult to be performed after the above problems occur. The solution is mainly to replace new spare parts, but the replacement cycle is long and the cost is high. The latest repair methods for contemporary hydraulic acrow props are based on polymer composite materials. Among them, the most mature application is the China coal Group technology system. It has excellent adhesion and good pressure resistance. It can not only meet the production and use requirements under the above working conditions, but also the operation process is simple and easy. It has no thermal influence and unlimited coating thickness. At the same time, the coating has excellent oil and corrosion resistance and self-lubricating functions, which ensure the wear resistance after repair, ensure the normal production of the enterprise, and avoid the deterioration of equipment components.

The above are the basic troubleshooting tips for the hydraulic acrow props. I hope that it can help more customers understand the machinery and equipment, provide support and help to ensure that customers and friends choose the use needs, and at the same time, can help more mining safety production provide support help.