Now everyone knows that the single hydraulic prop are mainly used in mines. In the underground, the hydraulic prop have the advantages and the safety of the operation of the suspension hydraulic prop is high.

The single hydraulic prop adopts electrophoretic coating in foreign countries. The hydraulic prop is in the water-soluble paint tank, the workpiece is the cathode, and a certain voltage and time are applied to form a paint layer of uniform thickness on all surfaces of the spring, which is cleaned and dried. The appearance is clean and dull, no particles, no exposure, the bonding force is not easy to fall off, the hardness is 3-4H, and the polyurethane cathodic electrophoretic coating of British LH company is adopted, and the flexibility is quite good. The operating environment has no strong solvent smell, less air pollution, simple wastewater treatment process for single hydraulic props, and adjusts the pH to allow the electrophoretic coating resin to settle and discharge the clean water.

The operation steps of the suspension hydraulic prop: add beam → add square wedges → determine the cleaning of the back and the position of the column → add liquid column (the working surface of the roof net is used to add the net first, and then operate in sequence).

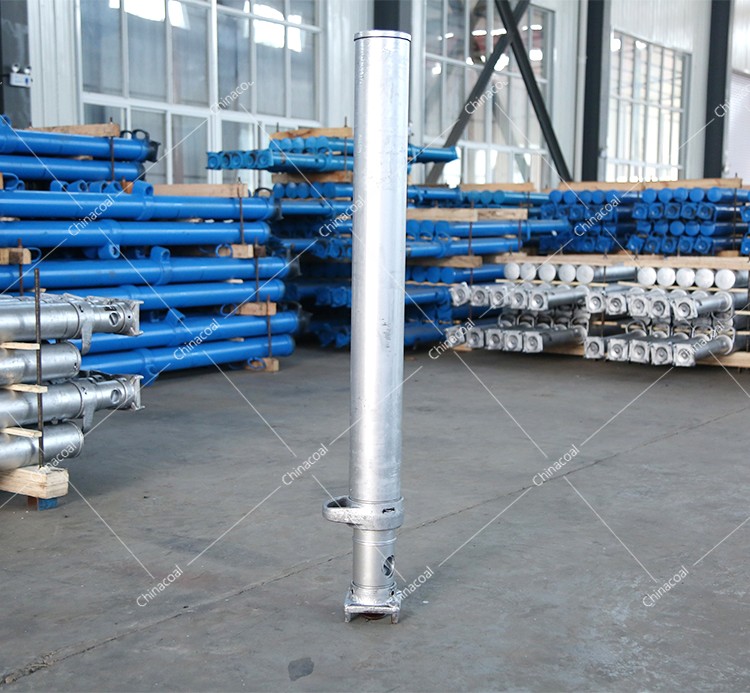

Single hydraulic prop hanging beam, one person stands in the complete position of the support, grasps the hinged top beam with both hands and sows into the set top beam earrings, another person stands on the sidewalk and inserts the top beam round pin, and uses a hammer to pin the round pin Enter the required location. Lift the ceiling beam and insert the adjusting angle wedge from bottom to top, leaving a gap of 0.1-0.15 meters between the beam and the ceiling. For coal mining face with shock pressure, the pillar can be replaced with a large-flow three-purpose valve to meet its support requirements. The DW single hydraulic prop is a fixed resistance prop. The DW single hydraulic prop can be used in combination with various ceiling beams, and can also be used as a main column.

DW single hydraulic prop uses domestic advanced EDA anti-corrosion technology to double the anti-corrosion ability of the surface of the living column. When in use, even if the surface of the active cylinder is punctured or violently collided, the substrate is exposed, and the large area of the substrate is corroded and the plating layer will not fall off. The single hydraulic prop has been used in our factory for many years, and the technology has reached the domestic advanced level. With zinc-nickel composite coating, the potential difference between the active base column and the coating is reduced, and it is difficult for a single hydraulic prop to form a primary battery. When the coating is damaged by impact, it will have self-protection ability, which is suitable for use in blasting working surfaces. The protection board used for the general mechanized coal mining and blasting mining face of coal mines can also be used for the comprehensive mechanized coal mining face.