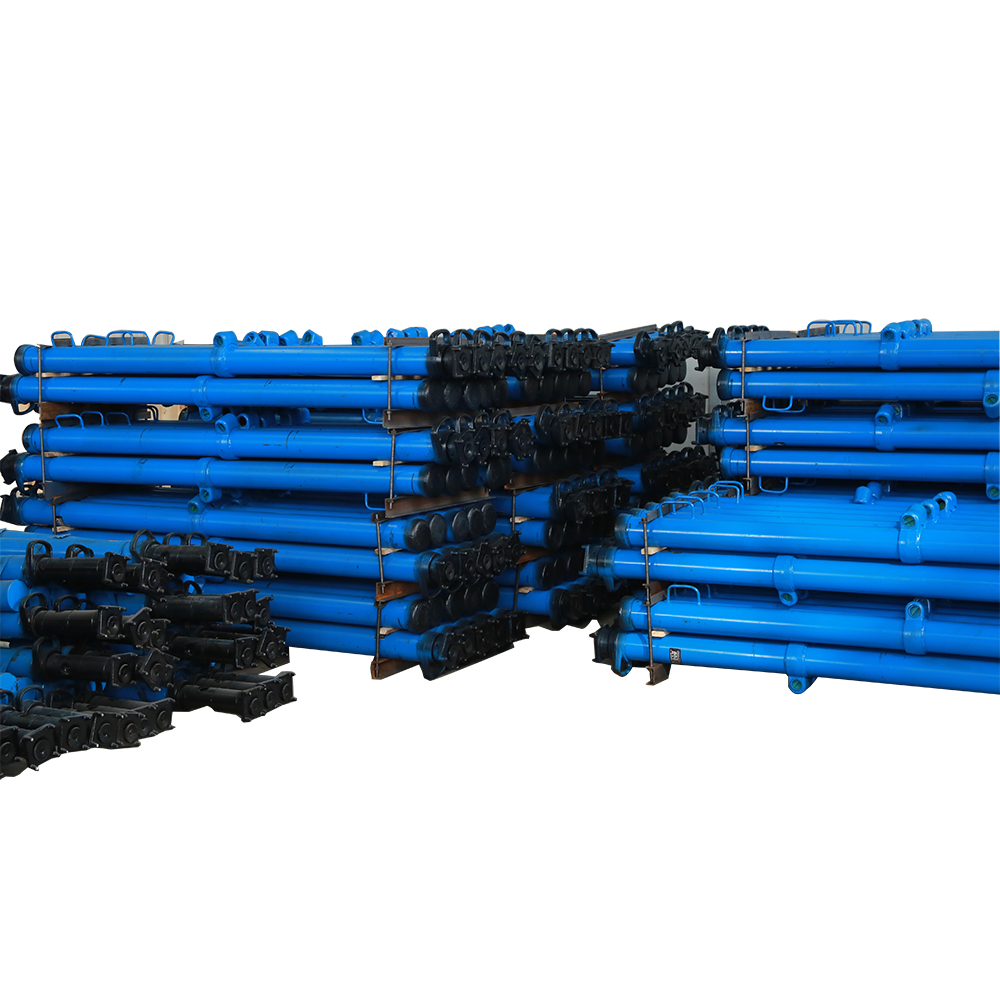

DWS25 double telescopic suspension Adjustable Prop sgives up the elongated cylinder, plunger and piston, no circular arc welding, no internal leakage, visual inspection with naked eyes, when the strut is exposed, the strut can be replaced at any strut, which more safely avoids the top deficiency of the strut and the cumbersome inspection work due to the existence of leakage inside the strut.

1. the working fluid of underground DN internal spray monobloc Adjustable Props is the 5th hydraulic oil, and when returning to the pillar, the Acrow Prop oil flows back to the plunger cavity of the cylinder to form a closed cycle;

2. pumps and piping systems, auxiliary equipment are not required, low cost;

3. it can still be used in places without trunk piping and pumping stations, with strong flexibility and easy and simple management;

4. because of the working fluid is closed circuit, lifting Acrow Prop oil return when the plunger cavity column itself to realize the hydraulic oil closed circuit, hydraulic oil consumption is very small;

5. the lifting Acrow Prop system is a closed system, the hydraulic oil does not overflow, does not pollute the environment, environmental protection, and the production surface is small, the surface environment is well maintained, the working conditions are better;

6. the propulsion valve is completely installed in the strut cavity, the possibility of external pollution is small, high reliability.