First, Define the use requirements

Support object quality and required support height: this is the basis for selecting theHydraulic Acrow Propsmodel and load carrying capacity. Ensure that the selected hydraulic pillar can withstand the expected load and provide sufficient support height.

Working environment: Consider factors such as the temperature, humidity and the presence of corrosive substances in the working environment. These factors will affect the selection of the seal material and hydraulic oil type of theHydraulic Acrow Props.

Installation: Select the support point, installation method and its operator convenience and other factors according to the actual working conditions. Ensure that the installation and use of hydraulic pillars are in line with the actual situation at the work site.

Second, pay attention to product quality

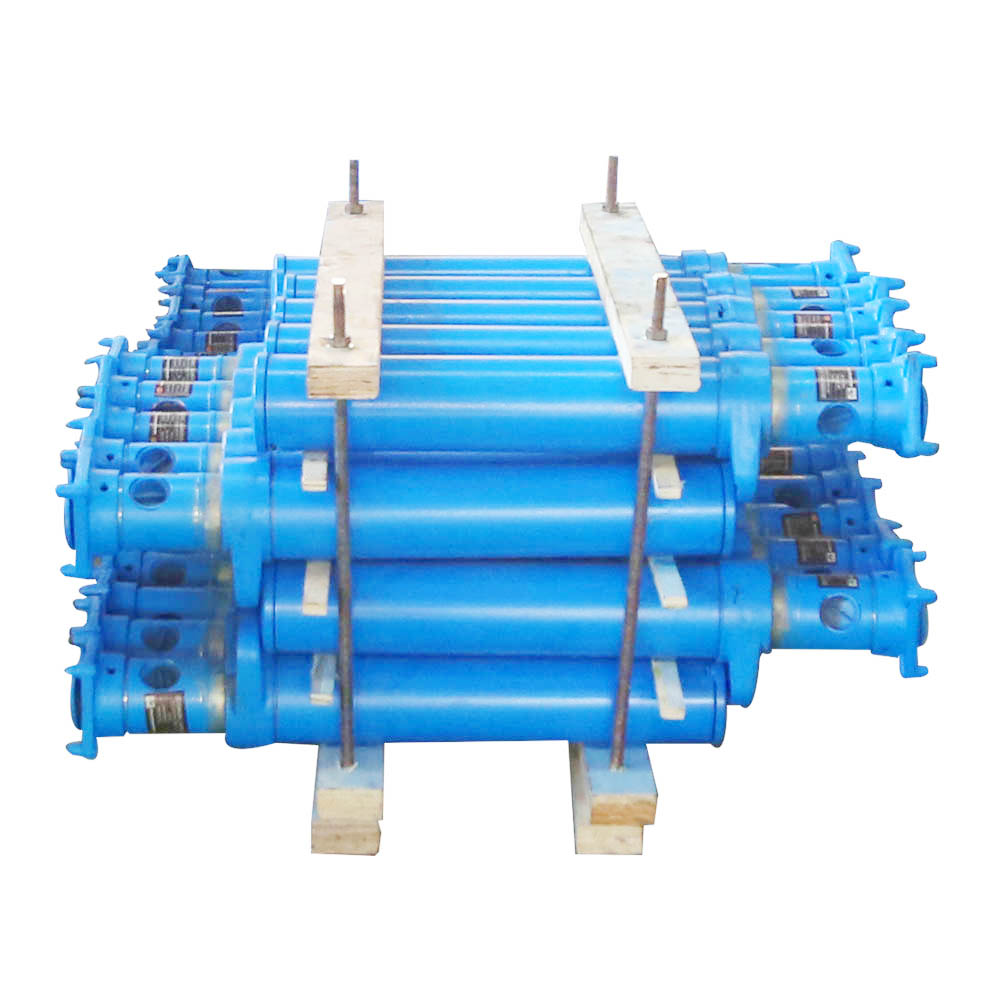

Structural features: the cylinder barrel of the hydraulic strut should be high strength, wear-resistant and corrosion-resistant, the sealing performance of the piston and the end cap should be good, and the liquid head part is reasonably designed to prevent the liquid from polluting the environment.

Strength and abrasion resistance: the strength, abrasion resistance and corrosion resistance of theSteel Acrow Propsshould meet the needs of the project to ensure its long-term stable operation.

Height and expansion: the height and expansion of theSteel Acrow Propsshould be adjustable to meet different engineering needs.

Simplicity of operation: choose Steel Acrow Props that are simple and convenient to operate, safe and reliable, in order to reduce the difficulty and risk of operation.