I. Daily inspection

Appearance inspection:

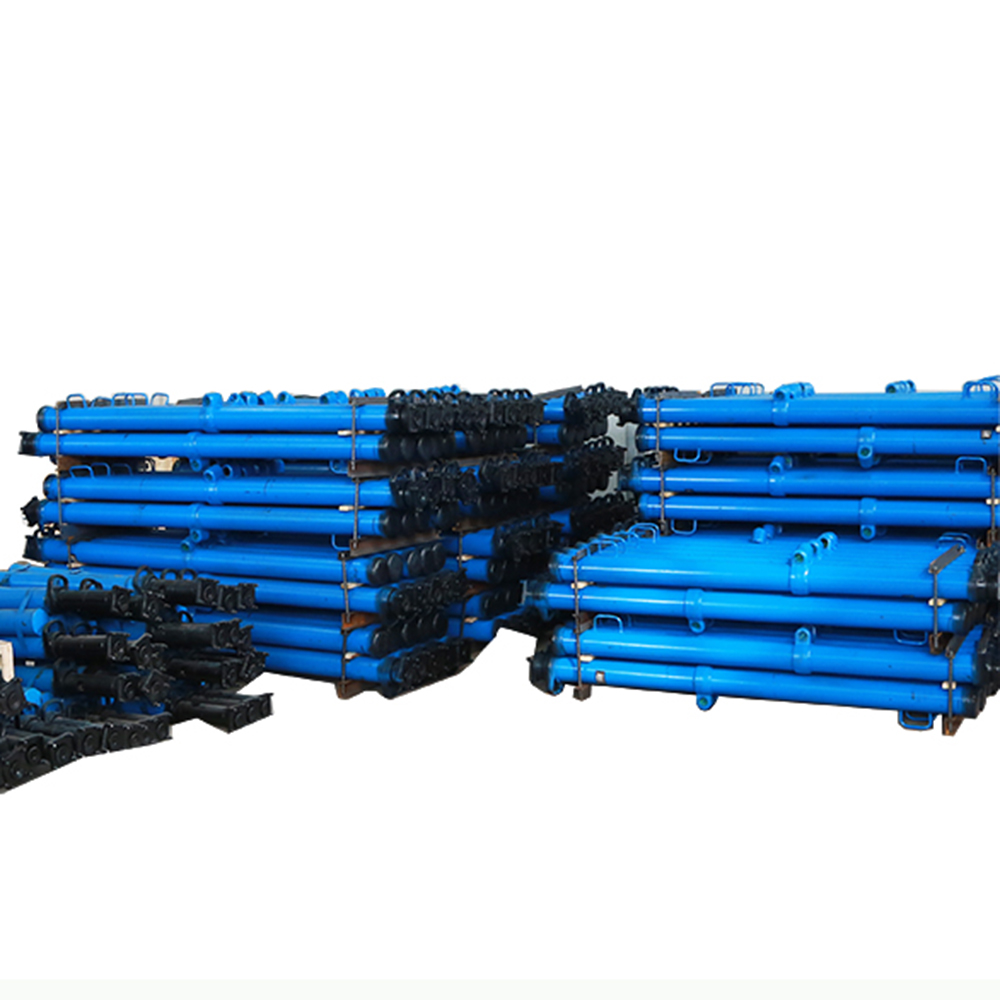

Check the appearance of theAdjustable Propsto ensure that it has no cracks, deformation or corrosion.

Check the connection parts of theAdjustable Propsto ensure that it is firmly connected and not loose.

Function check:

Check the control system, transmission system, power system and hydraulic system of the hydraulic pillar to ensure that each part functions normally.

Verify the support and adjustment function of the pillar to ensure that it can work normally.

II. Hydraulic oil management

Oil level check:

Regularly check the oil level ofHydraulic Propoil to ensure that it is within the specified range.

If the oil level is too low, the hydraulic oil should be supplemented in time.

Oil quality check:

Regularly check the oil quality of the hydraulic oil to ensure that it is clean and free of impurities.

If the oil quality does not meet the requirements, the hydraulic oil should be replaced with a new one immediately.

Replacement of hydraulic oil:

Hydraulic oil is susceptible to erosion by airborne impurities and moisture, so it needs to be replaced with new hydraulic oil periodically.

When replacing the hydraulic oil, the hydraulic system and tank should be thoroughly cleaned to avoid contamination of the new oil.

Third, cleaning and maintenance

Clean up dust and dirt:

Hydraulic Propwill inhale a large amount of dust and dirt during the working process, so they need to be cleaned regularly.

Use tools such as cleaners and brushes to remove dirt and dust from the surface of the strut.

Rust and corrosion prevention:

Apply rust or corrosion inhibitors to the surface of the strut to protect it from corrosion and rust.

Regularly inspect the strut's anti-corrosion coating to ensure it is intact.