Definition and importance of support force

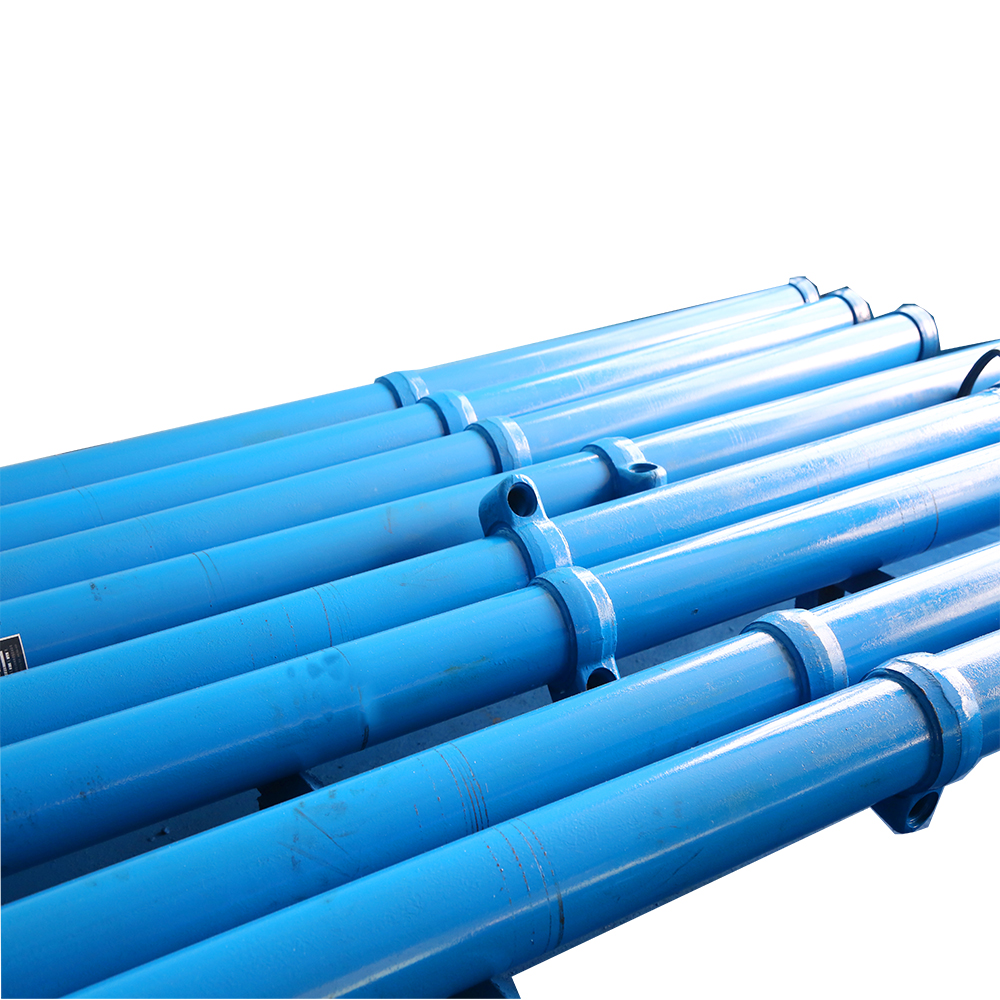

The support force of the Steel Acrow Props is the maximum resistance that the pillar can provide when it is under pressure. This index is of great significance for maintaining the stability of the mine tunnel, preventing the roof from falling and ensuring the safety of personnel.

Influencing factors of support force

Pillar model and specifications: different models and specifications of Steel Acrow Props have different support force. For example, the initial support force of Suspension Hydraulic Prop can reach 70~100KN, while some specific models of Suspension Hydraulic Prop may have higher support force.

Hydraulic pump station output pressure: the support force of the Suspension Hydraulic Prop is closely related to the output pressure of the hydraulic pump station. The higher the output pressure of the pump station, the greater the support force that the strut can provide usually is. However, it should be noted that high pump station output pressure may also lead to pillar damage or safety hazards.

Strut base area: the size of the strut base area directly affects its support force. The larger the base area, the larger the contact area between the pillar and the ground, which can disperse more pressure and improve the support force.

Support conditions and geological factors: support conditions (such as support density, support mode, etc.) and geological factors (such as coal seam thickness, roof lithology, etc.) will also have an impact on the support force of the Suspension Hydraulic Prop.

Measures to improve the support force

Selection of high-performance pillars: According to the support needs of the working face and geological conditions, select Suspension Hydraulic Prop with higher support force.

Optimize the location and selection of hydraulic pump station: ensure that the location of the hydraulic pump station is reasonable, and the output pressure is stable and high enough to meet the support force requirements of the pillars.

Increase the base area of the pillar: increase the base area of the pillar, improve the contact area between the pillar and the ground, so as to disperse the pressure and improve the support force.

Strengthen the support management: reasonably determine the support density and support mode, strengthen the support quality monitoring and management to ensure that the support effect meets the design requirements.