Choose suitable pillar specifications:

According to the working face mining height, the size of the roof pressure and other factors, choose the appropriate Suspension Hydraulic Prop specifications.

Ensure that the Suspension Hydraulic Prop can meet the support needs of the working face to avoid insufficient or excessive support.

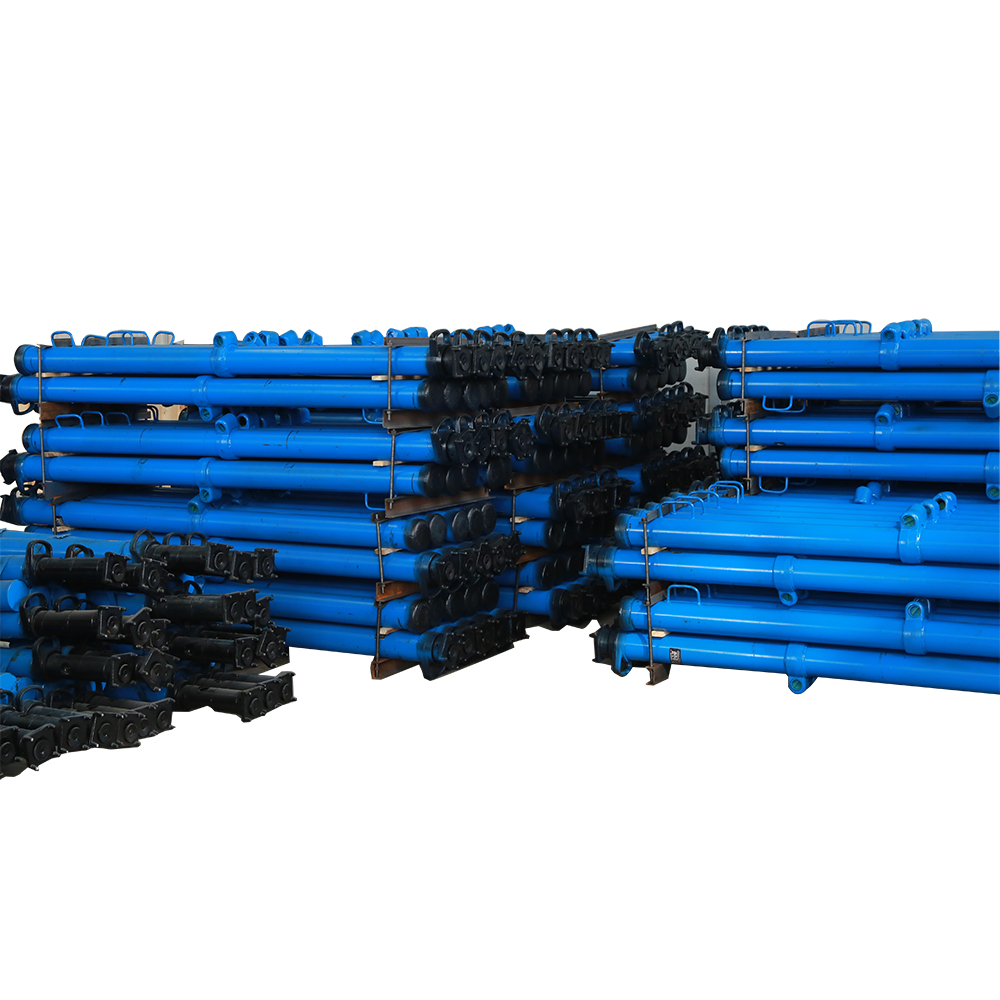

Transportation and storage:

During transportation, the Steel Acrow Props should be placed smoothly to avoid strong impact.

When storing, choose a ventilated and dry place without corrosive materials, and avoid water and collision.

The repaired Suspension Hydraulic Prop should be drained of the emulsion in the inner cavity, and the liquid injection hole and the column head hole should be plugged with a plug to prevent dirt from entering.

Supporting operation:

Before supporting, the top plate condition should be checked to ensure the stability of the supporting area.

When supporting, the Suspension Hydraulic Prop should be set perpendicular to the top and bottom plates, and have a certain angle of “meeting the mountain” to ensure the supporting effect.

When using the liquid injection gun, the valve nozzle should be flushed first, and then inserted into the liquid injection. In the process of liquid injection, it should be ensured that the liquid injection gun and the valve nozzle are connected tightly to avoid liquid leakage.

The strut must reach the specified initial support force before liquid injection can be stopped. The control of the initial support force can be realized by the constant pressure of the pump station.