1. Management before use

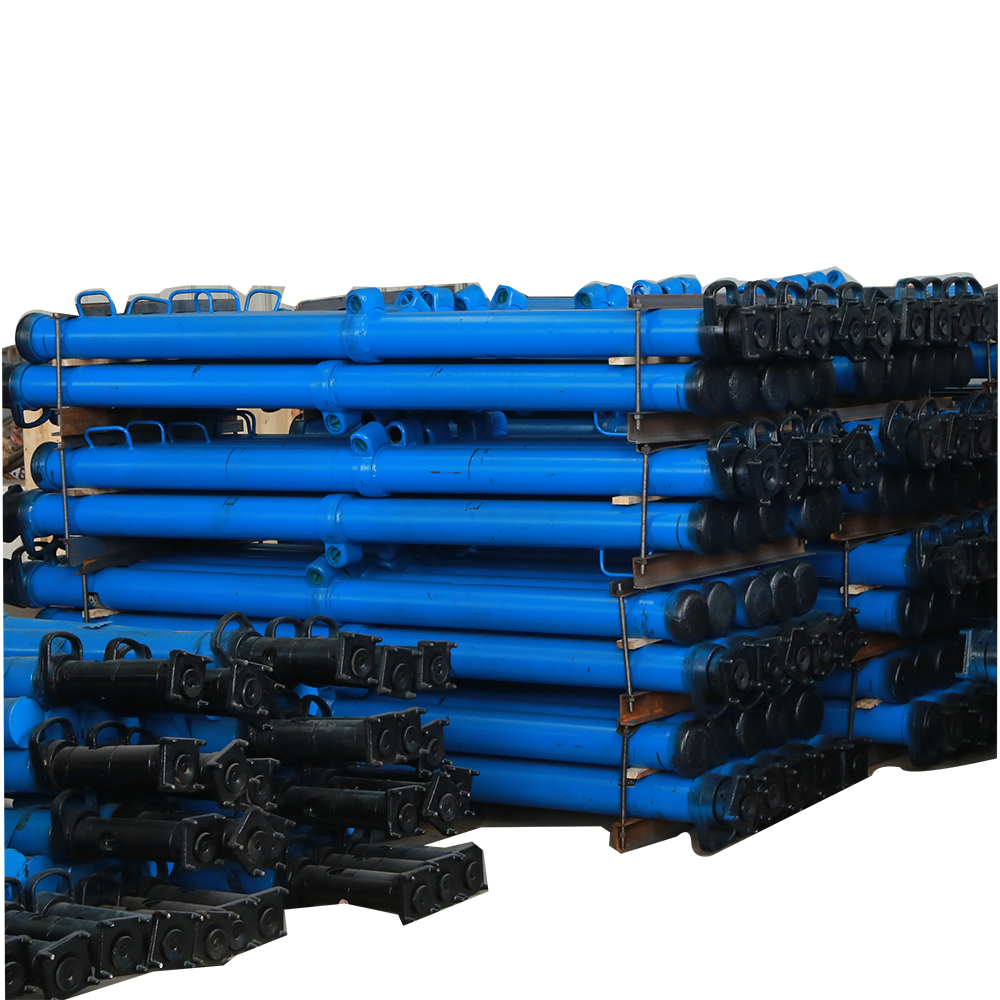

For the working face to be used with Steel Acrow Props, the first thing to do is to select the correct type according to the geological conditions of the working face and the necessary monitoring results. Only when the selection is appropriate, can the pillar give full play to its function and manage the roof plate well.

Prepare the support program, technical measures and safe operation procedures according to the production mode of the working face, and report them to the competent authorities for approval before implementation.

Establish the ledger according to the working face. Its content generally includes: date of well, quantity, type, amount of damage, maintenance time and root times, pillar technical performance measurement data, etc.

Strictly in accordance with the support procedures to ensure the quality of erection. To columns, rows of uniform spacing, horizontal rows, vertical rows. Hydraulic Acrow Props should be set up vertically on the top and bottom plates, and there should be an angle to meet the mountain and the angle should be appropriate.

When injecting liquid into the Steel Acrow Props, pay attention to the cleanliness of the liquid injection port of the three-use valve, and generally rinse it before inserting the gun for liquid injection.

Strictly manage the emulsion to ensure that its various performance index parameters compound requirements.

2. Maintenance management

Establish maintenance management system. In the process of underground support, pay attention to the damage of the Steel Acrow Props, when the strut is automatically unloaded and lowered, the unloading valve fails, and the surface of the strut has obvious mechanical deformation or mechanical abrasion that affects the action, etc., it should be timely ascended to the well for repair. Pillar in the well after 6 ~ 8 months of continuous use (mostly after a working face mining) or longer underground storage time, should be lifted to overhaul.

where the overhaul of the pillar must be tested, the contents generally include operation test, load bearing test, high and low pressure sealing test.