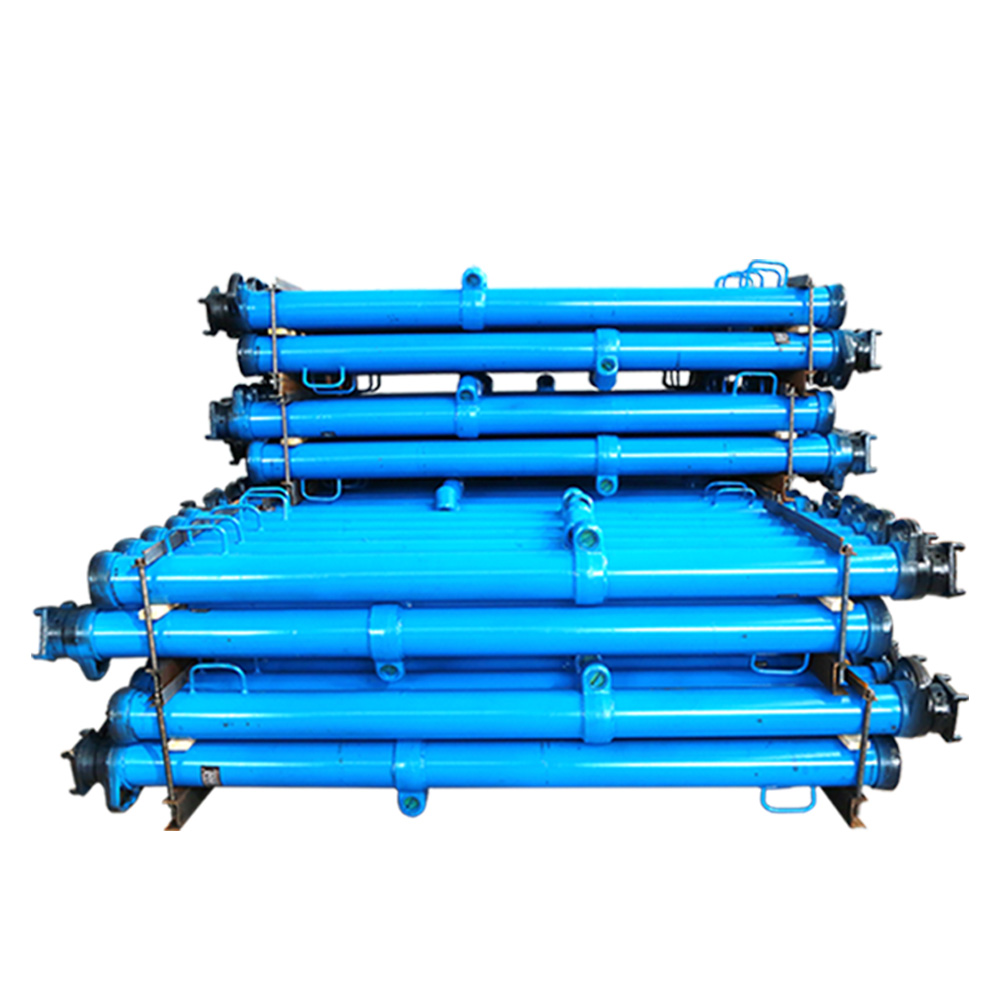

Coal mine underground monolithic Single Hydraulic Prop as a component of the monolithic mining support system, used to reinforce the top plate of the double wood - as a simple wall crack support, ground vibration risk of independent support of the top plate, as a long-wall roof support in other types of support system of the reinforcement elements.

Rising column, initial bracing process: when the live column is inserted into the injection hole of the three-use valve of the injection gun in the piping system, after hanging the locking sleeve, the injection gun is operated, and the high pressure of the pumping station opens the spherical check valve in the three-use valve through the top of the injection gun and injects into the live column, forcing the live column to rise up.

Carrying, overflow process: the live column will be in the bearing state after floating, with the extension of the support time, the top plate working surface load on the Hydraulic Prop increases, when the load borne by the Hydraulic Prop exceeds the rated working resistance, the high pressure liquid in the pillar cavity acts on the safety valve cushion force, more than the compression of the safety valve spring pre-adjusted to the compression force of the hexagonal guide sleeve, compression of the safety valve spring, the safety valve cushion and the hexagonal guide sleeve.

The safety valve cushion and the hexagonal guide sleeve move together, the safety valve cushion and the hexagonal guide sleeve move together, the safety valve cushion and the hexagonal guide sleeve move together. The safety valve pad and hexagonal guide sleeve move together, the safety valve pad leaves the valve seat, the safety valve opens, the liquid in the inner cavity overflows, and the column drops.