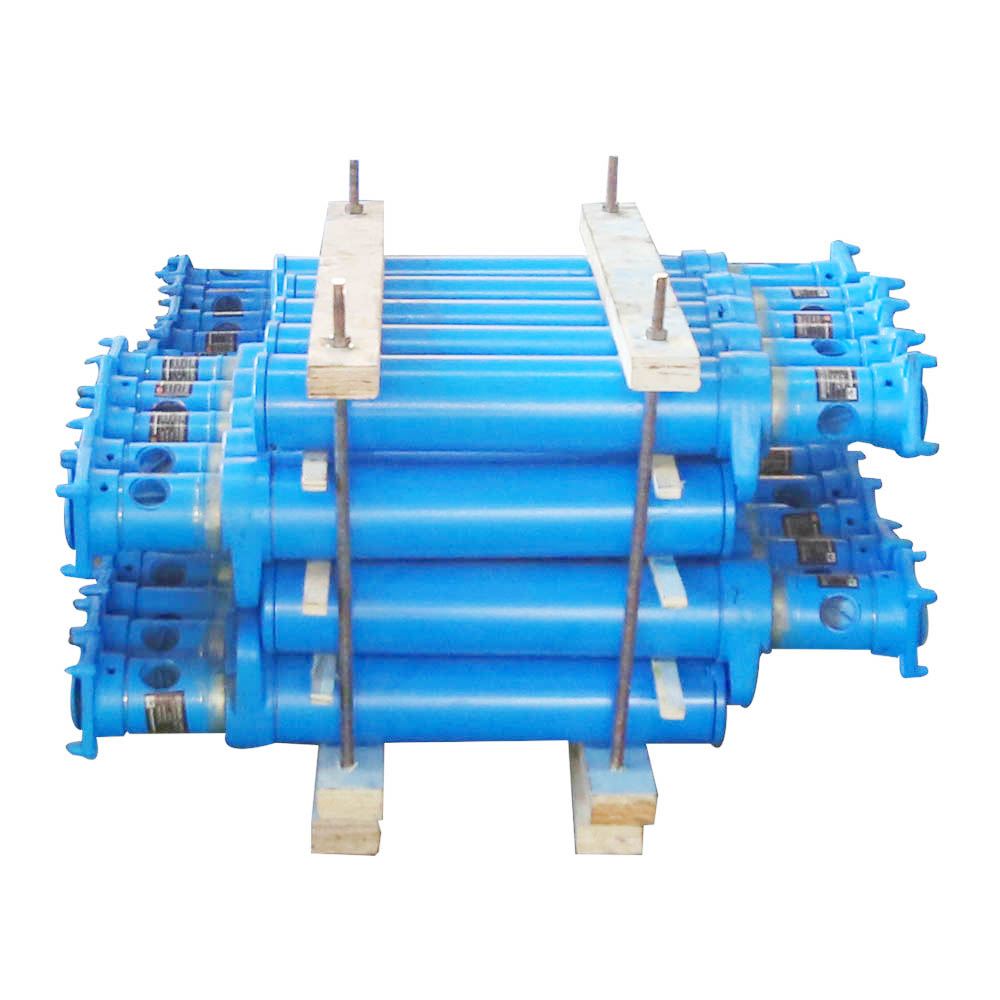

Installation and support

Installation position: The installation position of the Acrow Prop must be correct to ensure that the Acrow Prop can stably support the rock or coal seam and remain flush with the surrounding support equipment.

Supporting process:

When supporting the Acrow Prop, each group should not be less than two people, one person supporting the Acrow Prop and one person monitoring the safety.

Acrow Prop and roof beams should be reliably fit, not empty shoulder, and not hit on the floating coal, floating gangue. When encountering the soft bottom plate, the Adjustable Props should wear shoes.After the Adjustable Props support is stabilized, it is necessary to connect the rope in time to prevent the failure of the Adjustable Props from falling and hurting people.

Initial support requirements: the pillar must meet the rated initial support requirements. For example, the pillar diameter of 100mm shall not be less than 90kN, and the pillar diameter of 80mm shall not be less than 60kN.

Inspection and maintenance

Inspection before entering the well: Before entering the well, the Adjustable Props must carry out pressure test one by one to ensure that there is no pressure drop within 2 minutes, no leakage of the cylinder within 4 hours, no jamming of the lifting column and the restriction device is firm and reliable.

Daily use inspection: before using the Adjustable Props in each shift, the pillars at work must be tested and a good record ledger must be established. Damaged metal roof beams and failed Adjustable Props should be replaced in a timely manner.

Emergency treatment: When encountering abnormal conditions of the Acrow Prop, such as oil leakage, strange noise or instability, etc., stop using it immediately and repair or replace the strut in time.